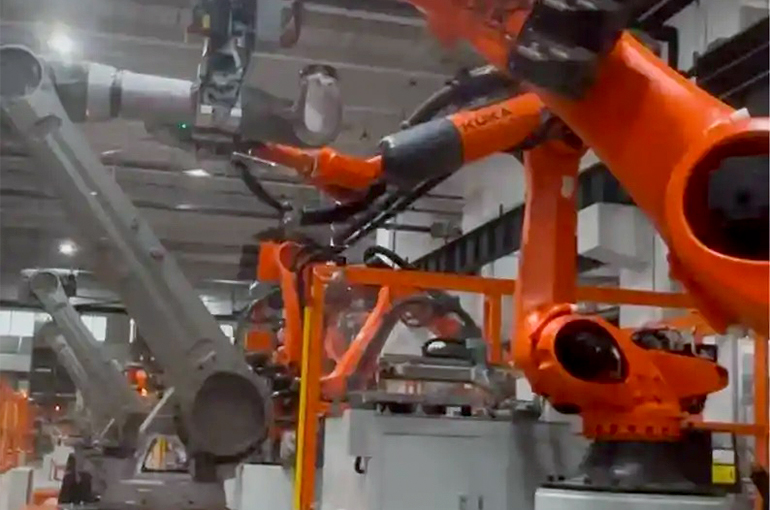

Robots Build Robots at Kuka's Guangdong Facility, Producing One Every Half Hour

Robots Build Robots at Kuka's Guangdong Facility, Producing One Every Half Hour(Yicai) Feb. 13 -- Robots are producing robots at German robot maker Kuka Group’s Shunde base in southern Guangdong province. One robot rolls off the assembly line, which is lined with robots, every half hour, Yicai noticed during a recent visit.

“If necessary, the production speed can be increased to one robot every 20 minutes, and it should be possible to further shorten this time to a few minutes or even one minute in the future,” Chen Feng, director of operations and human resources at Kuka’s China unit, told Yicai,

Kuka, which is one of the world's top four robotics companies, was acquired by Chinese white goods maker Midea Group in 2017. The Midea-Kuka Intelligent Manufacturing Technology Park in Shunde was put into production in 2019 and the East China base, which mainly services logistics clients and is located in Kunshan near Shanghai, started operations in 2023.

Kuka’s Shunde plant is one of China’s largest robot production bases and has an annual output of around 30,000 units. It also possesses research and development as well as manufacturing capabilities for the entire industrial chain, including light-load, heavy-load and collaborative robots, as well as core components such as reducers, motors and controllers.

"Kuka's robots are used in many industries, from cars, batteries, aerospace, electronics, consumer goods, and dairy products to new energy," Chen said. Augsburg-based Kuka provides its customers with a full range of solutions, and it has expanded the application of robots in the medical and logistics fields.

Kuka China started to produce the collaborative robot iiwa last year. This type of robot, which is mainly used in joint replacement surgery, orthopedic surgery and other medical fields, has a high output value per unit.

Local Suppliers

Kuka China has achieved independent control over the production technology used in robot bodies and has made significant progress in the technical development of core components, Chen said. "Except for some large reducers ,most other components are produced locally."

A large number of suppliers have gathered in the area around the Shunde base, forming a robust robotics industry ecosystem. Between 80 percent and 90 percent of the parts used in the Shunde factory are sourced from southern China, whereas previously robot parts suppliers were concentrated in eastern China, Chen said.

As suppliers and customers are located nearby, production costs at the Shunde base have been cut by around one third and the delivery cycle shortened to two to three weeks from two to three months, Chen said. It now takes less than a month for us to fulfill an order, he added.

Kuka plans to apply more AI technology in the production process. "In the future, Kuka China will integrate market and customer data into the company's AI platform to make robot debugging and installation easier," Chen said.

New orders jumped in January at Kuka China, mainly because new energy vehicle manufacturers are expanding their overseas operations and more 3C electronics suppliers are upgrading to smart manufacturing, Chen said.

Kuka's revenue exceeded CNY30 billion (USD4.1 billion) last year, a quarter of which came from China. As its products’ applications in the mid-to-high-end market expand, this proportion is expected to increase in the future, Chen said.

Editors: Tang Shihua, Kim Taylor