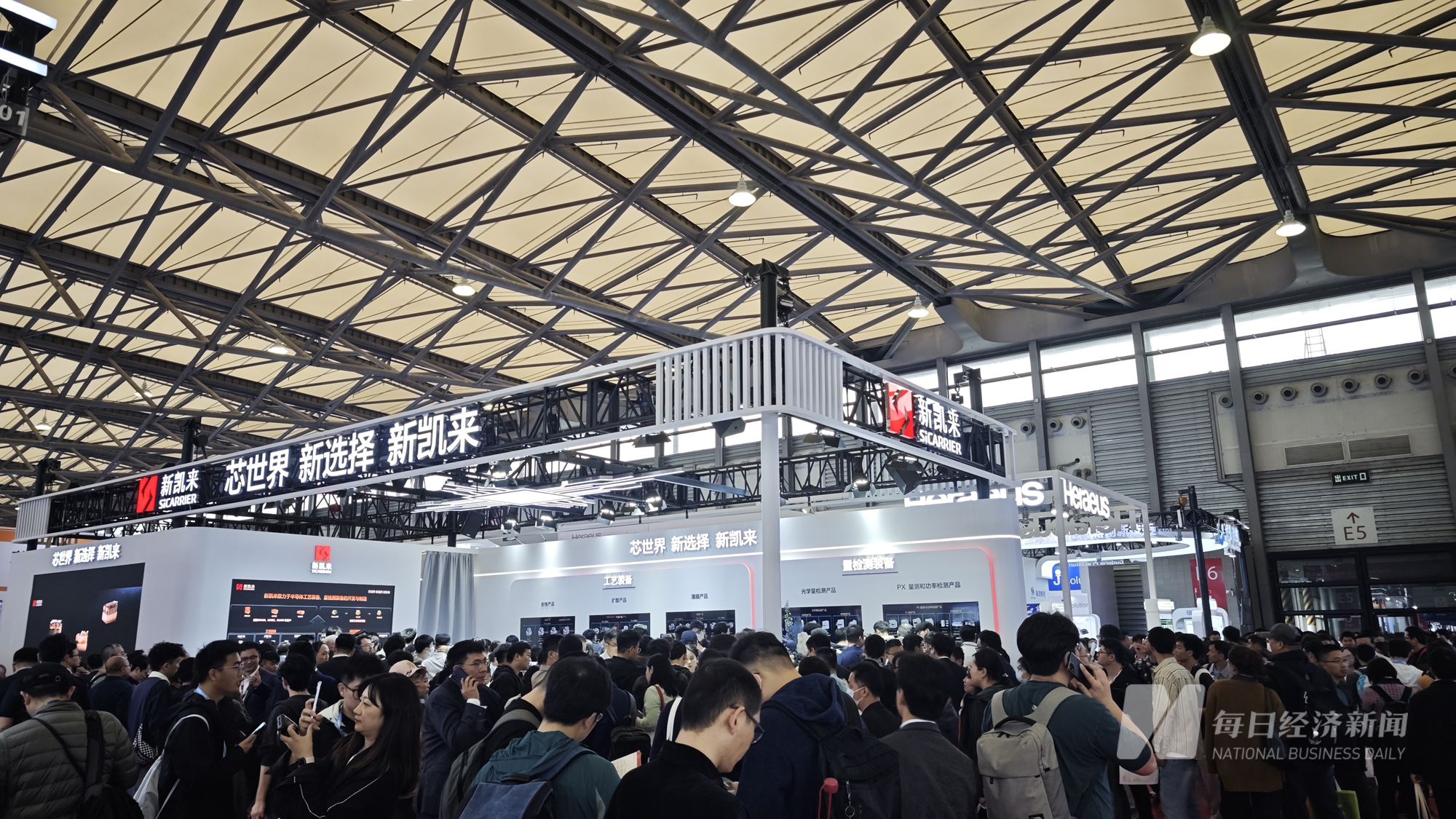

On March 27, at the SEMICON China 2025 exhibition site, the booth of Shenzhen Xinkailai Industrial Machinery Co., Ltd. (hereinafter referred to as Xinkailai) attracted much attention. This semiconductor equipment manufacturer covers the process equipment and quantity testing equipment matrix of multiple core processes of semiconductor manufacturing.

The

R&D of semiconductor equipment is not an overnight effort, and the company has formed a product matrix to meet the manufacturing needs of logic, DRAM (memory), NAND (flash memory) products, and supports the evolution of PlanarFET (Field Effect Transistor) and FinFET (FinFET (FinFET) to GAAFET (Total Surround Gate Transistor) process.

Image source: Photo by reporter Zhu Chengxiang

"Process equipment" multi-category product matrix

According to the Toubao Research Institute, semiconductor equipment can be divided into front-end equipment and back-end equipment, front-end equipment is mainly used for wafer manufacturing, involving silicon wafer processing, lithography, etching, ion implantation, thin film deposition, cleaning, polishing, metallization and other processes, the corresponding core special equipment includes lithography equipment, etching equipment, cleaning equipment, ion implantation equipment, thin film deposition equipment, mechanical polishing equipment, measuring equipment, etc., among which lithography equipment, etching equipment, Thin film deposition equipment is the three core equipment in the semiconductor front-end production process.

According to the International Semiconductor Industry Association (SEMI), front-end equipment (wafer manufacturing) accounts for about 80% of semiconductor equipment investment, and packaging and test equipment account for about 10% and 8%, respectively. Among the wafer fabrication equipment, etching equipment, thin film deposition equipment, and lithography machines accounted for 22%, 22%, and 17% of the value of front-end equipment, respectively.

Among the "process equipment" launched by New Kailai, etching equipment and thin film deposition equipment are included. Xinkailai named its etching equipment "Wuyishan", and its products include Wuyishan No. 1, Wuyishan No. 3 and Wuyishan No. 5.

Its thin film equipment covers three main thin film deposition equipment: CVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition) and ALD (Atomic Layer Deposition). Among them, the CVD includes Changbaishan No. 1 and Changbaishan No. 3; PVD includes Putuo Mountain No. 1, Putuo Mountain No. 2 and Putuo Mountain No. 3; ALD has Alishan No. 1, Alishan No. 2 and Alishan No. 3.

In addition to the two core equipment, Xinkailai has also launched epitaxial growth equipment (EPI) and RTP (rapid heat treatment equipment), EPI includes Emeishan No. 1, Emeishan No. 2 and Emeishan No. 3; The RTP includes Sanqingshan 1, Sanqingshan 2 and Sanqingshan 3.

SEMICON China 2025 Exhibition Site Image source: Photo by reporter Zhu Chengxiang

Break through the weak links and launch a variety of measurement products

According to the Toubao Research Institute, on the whole, China has a high localization rate in degumming, cleaning and etching equipment, and has made significant breakthroughs in CMP, heat treatment and thin film deposition in recent years, while it is still relatively weak in measurement, gluing and development, lithography, ion implantation and other equipment.

Among the products launched by the new Kailai, the optical measurement products include Tianmenshan DBO (diffractive overlay measurement) and Tianmenshan IBO (graphic overlay measurement); PX (Physical and X-ray) metrology products include Yimeng Mountain AFM (Atomic Force Microscopy Metrology), Chibi Mountain XP XPS (X-ray Photoelectron Spectroscopy Metrometry), Chibi Mountain XD XRD (X-ray Diffraction Metrometry) and Chibishan XF XRF (X-ray Fluorescence Spectroscopy Metrology); Power testing products include RATE-CP (Wafer Electrical Performance Testing), RATE-KGD (Power Die Electrical Performance Testing) and RATE-FT (Power Single Tube and Module Electrical Performance Testing).

It is worth mentioning that the EPI launched by Xinkailai this time is also the direction of the domestic semiconductor equipment leaders China Micro Corporation and North Huachuang.

NAURA (002371. SZ, share price 415.9 yuan, market value 222.05 billion yuan) 2023 annual report shows: "Epitaxial (EPI) equipment is a key equipment for material growth, which is widely used in integrated circuits, power semiconductors, compound semiconductors and other fields. By the end of 2023, NAURA has released more than 20 mass-produced epitaxial equipment, with a cumulative shipment of more than 1,000 cavities. The company's self-developed 12-inch atmospheric pressure silicon epitaxy equipment has achieved full coverage of logic chips, memory chips, power devices and characteristic processes, and all of them have been successfully mass-produced, becoming the benchmark products of customers. ”

China Micro Corporation (688012. SH, share price of 184.31 yuan, market value of 114.708 billion yuan) as early as February 2023 in the investor relations activity record form, said: "(The company) has more than ten years of experience in monocrystalline silicon epitaxy equipment, so we are now in full swing to develop EPI equipment for integrated circuits in silicon and germanium silicon." Because we have a lot of experience in thin film equipment, we are confident that we can develop a good EPI equipment. In addition, according to the 2024 performance report of AMEC: "The company's EPI equipment has successfully entered the stage of mass production verification of the client. ”

In addition, AMEC is also actively expanding its quantitative testing business. According to AMEC's announcement in December 2024, "as micro devices become smaller and smaller, testing equipment has become more critical equipment, and the market is growing rapidly, becoming the fourth largest equipment category accounting for about 11% of the total semiconductor front-end equipment market." The testing equipment market is mainly divided into optical testing equipment and electron beam testing equipment, of which the company has invested in the optical testing equipment sector, while Supermicro (a holding subsidiary of AMEC) plans to develop electron beam testing equipment, which will continue to expand the coverage of a variety of testing equipment. Electron beam detection equipment is the key equipment for yield control of chip manufacturing and advanced packaging process, which is very important for the development of new quality productivity represented by artificial intelligence in China, and is one of the shortcomings of China, which urgently needs to achieve a breakthrough of zero. ”

Ticker Name

Percentage Change

Inclusion Date