![[In Photos] Evergrande Chairman Tours Firm’s New Car Assembly Plants](https://img.yicaiglobal.com/src/image/2020/08/7055393667416064.jpg) [In Photos] Evergrande Chairman Tours Firm’s New Car Assembly Plants

[In Photos] Evergrande Chairman Tours Firm’s New Car Assembly Plants(Yicai Global) Aug. 7 -- China Evergrande Group, a property developer aggressively shifting into the new energy vehicle sector, recently showed off its brand new production lines in Shanghai and Guangzhou.

During a recent visit to the production bases, Chairman Xu Jiayin expressed his delight at seeing such world-class facilities. “I feel just like I did 28 years ago when I was a workshop director at Wuhan Iron and Steel,” he said.

At the start of this week, a unit of Guangzhou-based Evergrande unveiled six NEV prototypes under its Hengchi brand at special events held in Shanghai and Guangzhou. They included sedans, sport utility vehicles, and multi-purpose vehicles numbered Hengchi 1 to Hengchi 6.

Equipment is being procured and installed at the plants, which are being built in accordance with Industry 4.0 standards and are equipped with 2,545 intelligent robots, which will enable a car a minute to be produced.

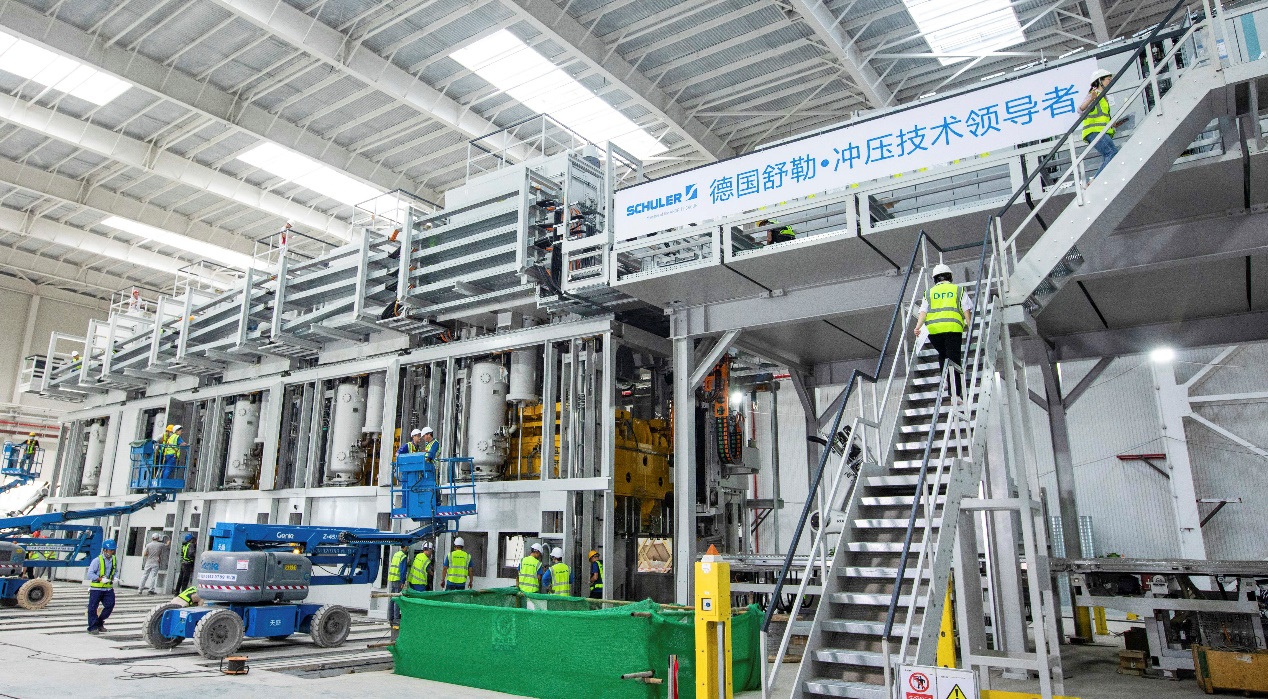

The four workshops are equipped with Germany-based Schuler Group’s automatic stamping production line, intelligent equipment from Germany’s Kuka and Japanese firm Fanuc, as well as German firm Durr’s automated coating production and assembly lines, all of which are world-leading.

Take the car body workshop as an example, the intelligent robots on each production line work together to easily complete the welding and shaping of the white body, and can run automatically 24/7.

Evergrande Chairman Xu Jiayin tours the new car plant.

Technicians check smart robots on the factory floor.

The stamping workshop.

The body workshop.

A Hengchi car.

Editor: Peter Thomas